Security Barriers (147)

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

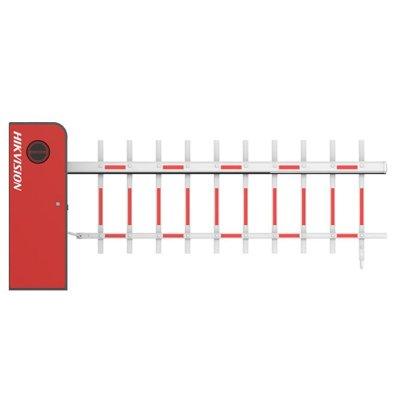

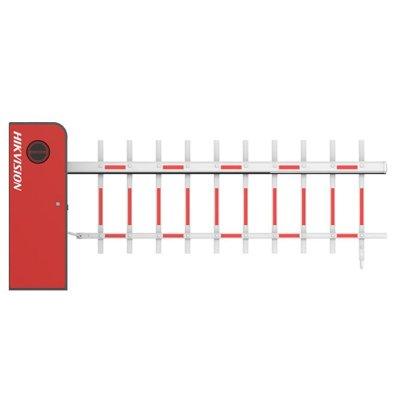

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required). Intergated with strip light and body indicator to show barrier gate status

Add to Compare

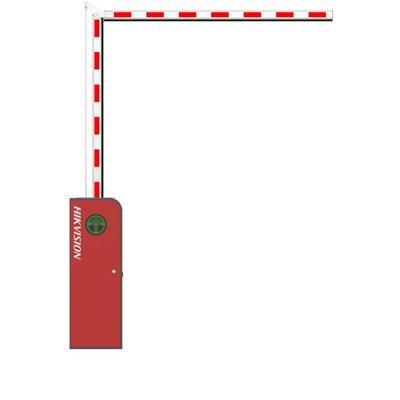

Supports convenient side installation with compact structure. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Delayed boom pole closing. Supports 1 to 99 seconds.

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required). Intergated with strip light to show barrier gate status

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required). Intergated with body indicator to show barrier gate status

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required). Intergated with body indicator to show barrier gate status

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required). Intergated with body indicator to show barrier gate status

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required). Intergated with strip light to show barrier gate status

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required). Intergated with strip light to show barrier gate status

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Adopts integrated machine core. Parallel gear decelerates linkage arm transmission to ensure stability and efficiency. Supports convenient side installation with compact structure. Adopts quenching process for carbon steel gear to realize wear-resistant and impact-resistant functions and extend product life. Adopts small DC brushless motor with low noise to increase output torque and realize precise intelligent control. Supports rebound for obstacle and opening priority. Adopts DC variable frequency control to enable smooth operation with fast boom pole opening and slow boom pole closing. Supports event log to enable convenient monitoring. Supports multiple anti-fall modes such as IR, vehicle detectors, and radars. Supports fault code detection on the nixie tube, log record, and abundant status indicating. Based on the fault code displayed on the nixie tube, you can realize quickly problems locating and maintenance. Supports manually opening boom pole. You can turn hand wheel to keep barrier gate opening during power cutoff. Delayed boom pole closing (10 s delay time by default). Supports 99 shifts (initial status 2 s, 2 s gap between each shift). Supports auto boom pole opening during power cutoff. The barrier gate can open automatically to allow fire trucks in (optional components required).

Add to Compare

Traffic access control professionals can now set up Delta Scientific MP5000 portable barriers on concrete, asphalt, compacted soils or vegetation in 15 minutes or less to provide certified M50 stopping power. Original models provide M40 protection while the new models stop 15,000 pound (6804 kg) medium-duty trucks traveling at 50 mph (80.4 kph). Significantly, Delta are releasing the first M50 rated portable barrier system to the world at a time when military grade portable protection is imperative. With over 2,000 working units in the field over the past decade, this portable barrier has proven its capabilities to clients throughout the world. Especially important to our government customers and select commercial clients, high security professional can now protect assets that have traditionally required an M50 rating with a portable product. The MP5000 is available in 12-, 16- and 20-foot openings. It is easily towed behind a truck or other vehicle to its location where it sets up in less than fifteen minutes. Once it has performed its duty, it is quickly packed up and towed to its next project. The MP5000 is self contained and battery powered. It has been seen at G20 meetings, presidential inaugurations, papal parades, international embassies, municipal parades, Mardi Gras, stadiums and other civilian locales from the United States to Australia and is especially popular at forward operating military bases from Afghanistan through the rest of the world.

Add to Compare

This quick installation surface mounted barrier has a single buttress that houses all the necessary components to run the unit. Simply bring in power to the buttress side of the barrier and run your control wire to your desired location and you are ready to go. This barrier can be left handed and right handed to cover larger openings or orient the barrier as needed for power.

Add to Compare

The TT207SFM is a K12 rated barricade 15,000 pound truck at 50 mph. It comes in two versions, surface mounted for parking ramps and with the standard 13 inch foundation. This high security barricade is also available with a debris screen. When the K-12 barricade is in the up position, the hydraulics are protected by the heavy metal ramp plate. Widths available: 12 foot to 24 foot clear opening.

Add to Compare

Delta Scientific's HD200 features a 0.63 second emergency fast operation (EFO). Created for high traffic, densely-populated locations that need high speed open/close rates to get many vehicles in and out as well as very fast closing rates to protect the people, the HD200 highlights a very fast open/close cycle of 2-5 seconds. The fast operating HD200 barrier will bring to a full stop a 7.5 ton (6803.9 kg) medium duty truck travelling 30 mph (48.3 kph) in less than 3.3 feet (1 meter). The truck rebound after impacting the barrier was an incredible 11.5 feet (3.5 m) in its crash test. This results in a crash rating of ASTM M30/P1. With its 0.63 second EFO speed, the HD200 barrier will stop and destroy a vehicle moving at 30 mph (48.3 kph), equivalent to 44 feet (13.4 m) per second, if triggered within 50 feet (15.2 m) of the barrier. Especially in high traffic, high volume locations, the barrier is open much of the time, letting vehicles through. Therefore, when the location is heavily populated as well, the barrier must open frequently but, as importantly, close quickly. With a 24-inch (61 cm) shallow foundation and fully enclosed, flush mount design, the HD200 obviates the concerns of interference with buried pipes, power lines and fiber optic communication lines in urban applications. The shallow foundation also reduces installation complexity, time, materials and corresponding costs. The HD200 is perfect for high water table locations and areas with corrosive soils. It provides low maintenance as its totally enclosed face is easily removed for access. Leveraging the latest technologies, the HD200’s breakthrough EFO can be remotely controlled via fiber optics, touch screen control panels, NEMA rated control button panels and simple key switches. The HD200 barrier also features a full range of diagnostic indicators for early detection of any difficulties. Projected life expectancy of the HD200 is 20+ years.

Add to Compare

The first in a new category of commercial, crash-tested vehicle barriers, the DSC1000 is a self-contained unit that is stored and towed on its own trailer. Using Delta's Soft Stop technology, the DSC1000 stops such drivers from inflicting harm upon pedestrians and themselves. Light enough to be towed by a golf cart and set up in only 10 minutes. The barricade’s self-contained power system provides all the power necessary to raise and lower the unit onto its trailer and open and close the barrier. This battery-powered system re-charges with a solar panel or external means. Controls can be locked or operated at the barricade or remotely.

Add to Compare

The DSC1100 provides security against vehicle-based terrorism or thefts for high-cycle locations such as the entrances to large office facilities, government agencies and military bases. Able to be deployed in high traffic locations for full manual or automatic operation within two hours, Delta Scientific’s quick deployment modular Series DSC1100 Barricade features a phalanx-type rising plate barrier mounted within multiple inertial pods. The plate barrier lies level to the ground to allow vehicles to pass and is raised or lowered into position utilizing a hydraulic cylinder driven by a Delta Hydraulic Power Unit or manually operated.

Add to Compare

Delta Scientific Corporation TT212EC Enhanced Chain Crash beam barrier has been certified by the U.S. Department of State to stop a 15,000 pound vehicle in less than 20 feet. Actual penetration is 5 feet. Both hydraulic and manual versions are available.

Add to Compare